Die-Vac Plastics is a one stop shop for your packaging needs. Our 6,000 sq. ft. facility is fully equipped to supply the following services:

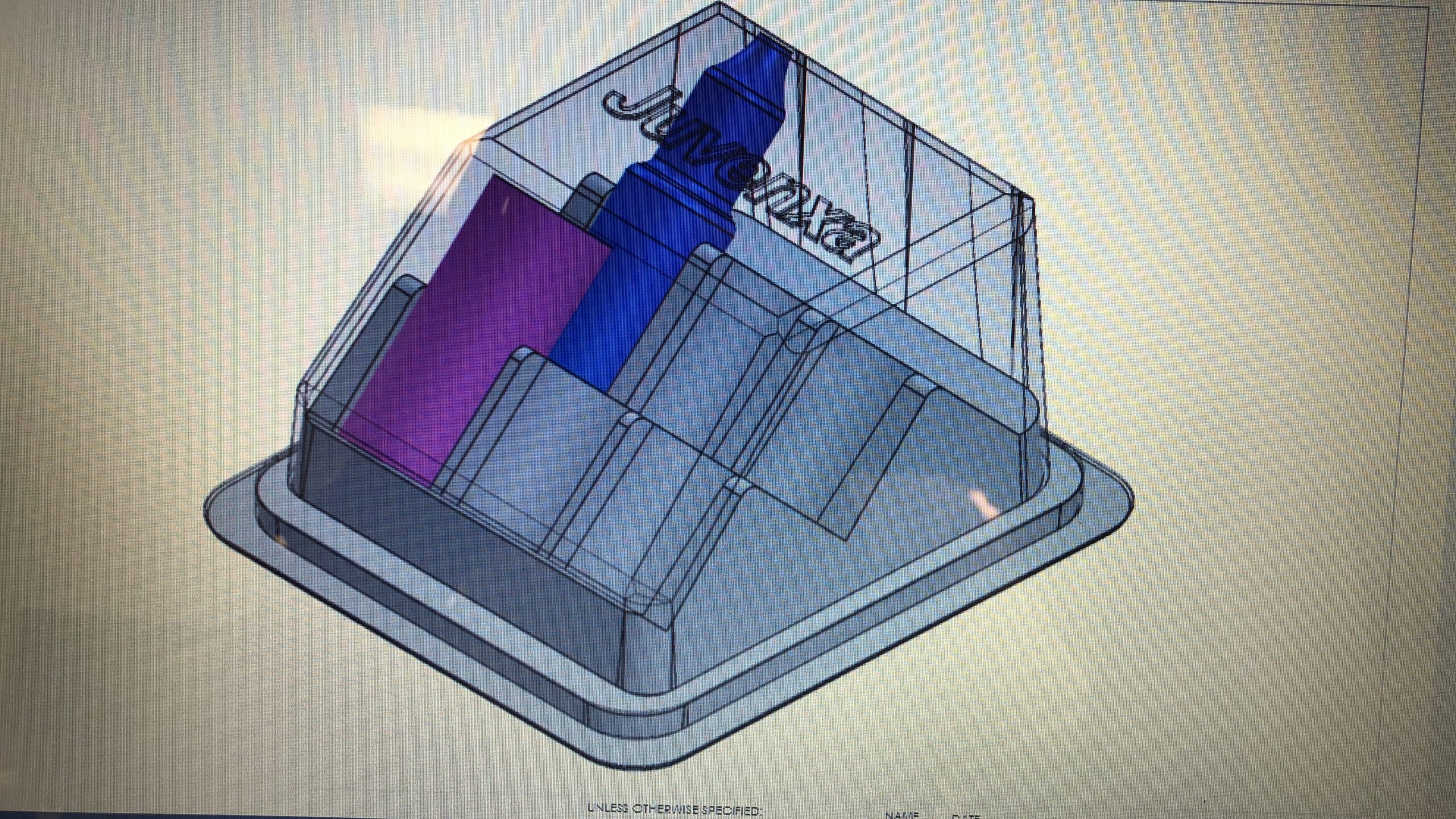

COMPLETE PACKAGE DESIGN AND ENGINEERING

We use state of the art CAD software to guarantee the design and functionality of our packaging will meet the most demanding needs in your industry

COMPLETE IN-HOUSE TOOLING FABRICATION

We have a full CNC machine shop ready to fabricate the necessary molds and tooling to complete your packaging projects, and guarantee in time project turnaround time

PRODUCT PROTOTYPING

Die-Vac Plastics designs and produces digital CAD prototypes as well as real samples usually within 2 weeks of your order to verify looks and product fit match the requirements of our most demanding customers

TOP QUALITY MANUFACTURING

Our manufacturing floor is equipped with modern thermoforming equipment, capable of short and long runs. Quality inspections are part of our process to guarantee that every package that leaves our facility meets all required specifications.

BLISTER AND CLAMSHELL PACKAGING FULLFILMENT AND SEALING

We can take care of final fulfillment for your packaging projects

Weather you need blister packaging sealing, clamshell ultra-sonic welding, we have the necessary equipment get your product ready for the market