CNC Machine Services Miami Fl, Ft Lauderdale Fl, Orlando Fl, Jacksonville, Tampa, Ft Myers, Sarasota FL

CNC Machine Services Miami Fl, Ft Lauderdale Fl, Orlando Fl, Jacksonville, Tampa, Ft Myers, Sarasota FL

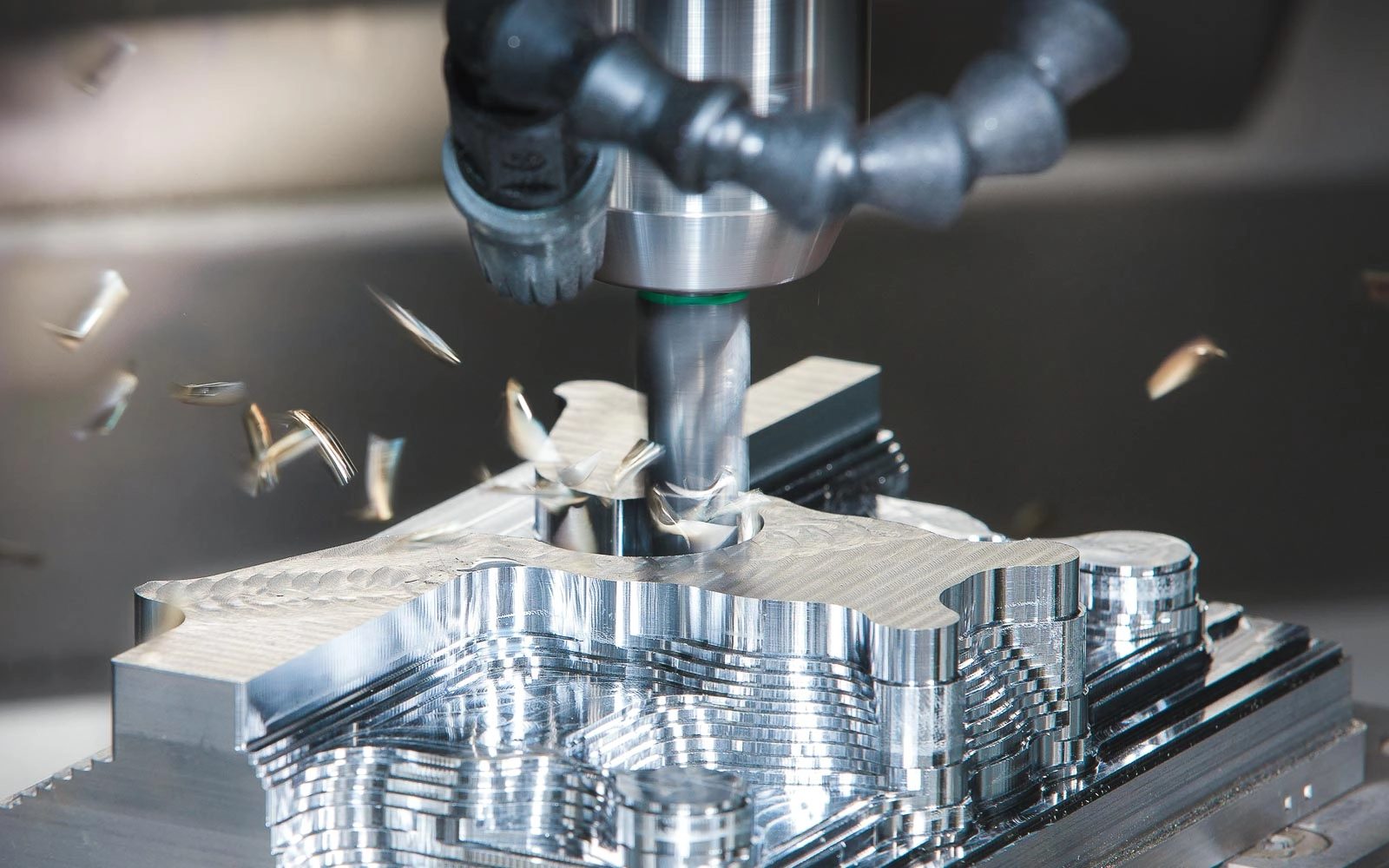

Precision Tooling & Machining — In-House & On Demand

At Die Vac Plastics, we’re more than a packaging provider. We operate a full, on-site CNC machine shop that underpins everything from prototype tooling to high-accuracy production molds and fixtures. Because we control machining in-house, we can guarantee faster turnaround, tighter tolerances, and full integration with your packaging project.

Our CNC Capabilities

We leverage state-of-the-art CNC equipment and skilled operators to deliver:

| Capability | Description / Benefits |

| High Precision Tolerances | Consistent accuracy for tight fits, mating parts, and critical geometries. |

| Multiple Materials | We machine ferrous and non ferrous materials, engineering plastics, acrylics, composites, and any other tooling materials. |

| Rapid Prototyping & Tooling | From concept to molded tools, we can machine patterns, cavity masters, and inserts. |

| Small to Medium Runs | Ideal for tooling trials, bridge production, or low-volume parts before full tooling. |

| Finishing & Post-Processing | Deburring, smoothing, polishing, chamfering, and more to prepare parts for use. |

Why Choose DieVac for CNC Machining?

- Seamless integration with packaging projects

Since we also handle design, thermoforming, vacuum forming, and sealing, your CNC tooling is fully aligned with your final packaging. No miscommunication, fewer delays. - Speed & responsiveness

With machining under the same roof, we respond faster to revisions, tooling tweaks, or urgent requests. - Quality you can trust

Every machined component passes strict inspection to ensure dimensional accuracy and functional integrity before moving to the next stage. - Cost-effective for one-offs and tooling

If you’re validating a design or making advanced packaging tools, CNC offers flexibility without massive setup costs.

Common Applications

- Mold cavity plates, cores, and inserts

- Tooling patterns for blister, clamshell, and vacuum-formed parts

- Fixtures, jigs, and mechanical components used in packaging lines

- Prototype parts to test fit/function before full tool production

- Machine replacement parts

- Any other special engineering project

How the Process Works

- Design & review

You supply CAD models or drawings; our team reviews for machinability, draft, and tolerances.

(We also offer design consultation.) - Material & tooling selection

Based on your needs, we select the ideal material (e.g. aluminum, tool steel, UHMW, acrylic) and cutting strategies. - Machining & inspection

The CNC program is optimized, cut, then inspected using high-precision metrology to verify tolerances. - Post-processing

Finishing steps are applied (deburr, polish, chamfer, etc.) and parts are cleaned, ready for next stage. - Integration or delivery

Machined components either move directly into your packaging tool or are shipped to you.

Get Started — Let’s Build Your Tooling

- Submit your CAD file or drawing

- Let us review and suggest machining strategies

- Receive a quote and lead time

- Watch us transform your concept into a high-precision tool

Ready to move your project forward? Contact us for a free consultation and quote — we’ll make sure your CNC components meets the most demanding specifications.