CNC Machine Services

CNC Machine Services

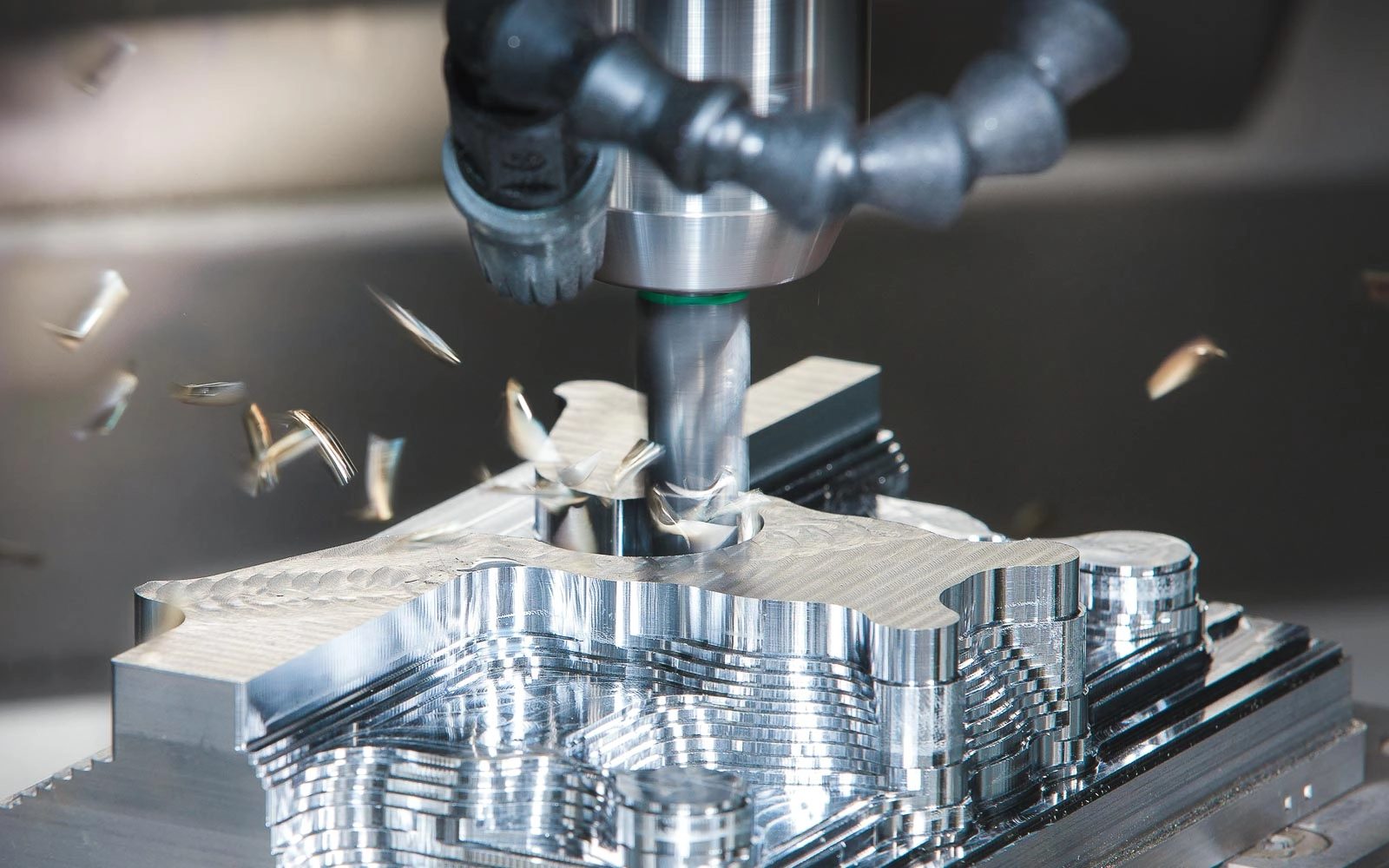

Precision Tooling & Machining — In-House & On Demand

At Die Vac Plastics, we’re more than a packaging provider. We operate a full, on-site CNC machine shop that underpins everything from prototype tooling to high-accuracy production molds and fixtures. Because we control machining in-house, we can guarantee faster turnaround, tighter tolerances, and full integration with your packaging project.

Our CNC Capabilities

We leverage state-of-the-art CNC equipment and skilled operators to deliver:

| Capability | Description / Benefits |

| High Precision Tolerances | Consistent accuracy for tight fits, mating parts, and critical geometries. |

| Multiple Materials | We machine ferrous and non ferrous materials, engineering plastics, acrylics, composites, and any other tooling materials. |

| Rapid Prototyping & Tooling | From concept to molded tools, we can machine patterns, cavity masters, and inserts. |

| Small to Medium Runs | Ideal for tooling trials, bridge production, or low-volume parts before full tooling. |

| Finishing & Post-Processing | Deburring, smoothing, polishing, chamfering, and more to prepare parts for use. |

Why Choose DieVac for CNC Machining?

- Seamless integration with packaging projects

Since we also handle design, thermoforming, vacuum forming, and sealing, your CNC tooling is fully aligned with your final packaging. No miscommunication, fewer delays. - Speed & responsiveness

With machining under the same roof, we respond faster to revisions, tooling tweaks, or urgent requests. - Quality you can trust

Every machined component passes strict inspection to ensure dimensional accuracy and functional integrity before moving to the next stage. - Cost-effective for one-offs and tooling

If you’re validating a design or making advanced packaging tools, CNC offers flexibility without massive setup costs.

Common Applications

- Mold cavity plates, cores, and inserts

- Tooling patterns for blister, clamshell, and vacuum-formed parts

- Fixtures, jigs, and mechanical components used in packaging lines

- Prototype parts to test fit/function before full tool production

- Machine replacement parts

- Any other special engineering project

How the Process Works

- Design & review

You supply CAD models or drawings; our team reviews for machinability, draft, and tolerances.

(We also offer design consultation.) - Material & tooling selection

Based on your needs, we select the ideal material (e.g. aluminum, tool steel, UHMW, acrylic) and cutting strategies. - Machining & inspection

The CNC program is optimized, cut, then inspected using high-precision metrology to verify tolerances. - Post-processing

Finishing steps are applied (deburr, polish, chamfer, etc.) and parts are cleaned, ready for next stage. - Integration or delivery

Machined components either move directly into your packaging tool or are shipped to you.

Get Started — Let’s Build Your Tooling

- Submit your CAD file or drawing

- Let us review and suggest machining strategies

- Receive a quote and lead time

- Watch us transform your concept into a high-precision tool

Ready to move your project forward? Contact us for a free consultation and quote — we’ll make sure your CNC components meets the most demanding specifications.